Key takeaways:

- A manufacturer produces the goods you intend to sell in your e-commerce store, while a supplier deals with procuring said products.

- You can find reliable manufacturers by visiting online platforms, interviewing fellow business owners, or attending trade shows.

- Finding a suitable manufacturer will help improve your business operations by optimizing production, thereby improving your margins.

When starting a business, learning how to find a manufacturer is one of the most important steps in turning an idea into a real, sellable product. Your chosen manufacturer will influence your product quality, production costs, timelines, and even how smoothly your business can scale over time. A strong partnership can set you up for long-term success, while the wrong fit can lead to delays, quality issues, and unexpected expenses.

Whether you’re launching your first product or looking to switch suppliers as your business grows, knowing how to find a manufacturer—and how to evaluate your options—can save you time and costly mistakes.

This guide breaks down the process in a clear, practical way, helping you understand where to look, what questions to ask, and how to choose a manufacturer that aligns with your product goals and business needs.

How to find manufacturers?

Finding a manufacturer isn’t just about locating a factory that can produce your product. It’s about following a structured process that helps you identify reliable manufacturing partners, compare options, and make informed decisions before committing to production. Skipping steps or rushing this stage can lead to misaligned expectations, inconsistent quality, or higher costs down the line.

To avoid those issues, it helps to approach the search methodically. Here’s what you need to do:

- Define your needs and product specifications

- Decide if you want domestic or overseas manufacturing

- Research via Google Maps and online directories

- Attend trade shows and local industry events

- Ask business owners and browse online forums

- Do background checks

- Ask questions

- Compare quotes and samples from multiple manufacturers

- Calculate your gross margins

- Check contract policies

- Negotiate

- Order your first items

1. Define your needs and product specifications

Before reaching out to manufacturers, it’s important to clearly define what you need and what you’re trying to produce. This step helps you narrow down the type of manufacturing partner that actually fits your product, rather than wasting time with suppliers who aren’t equipped to support your goals.

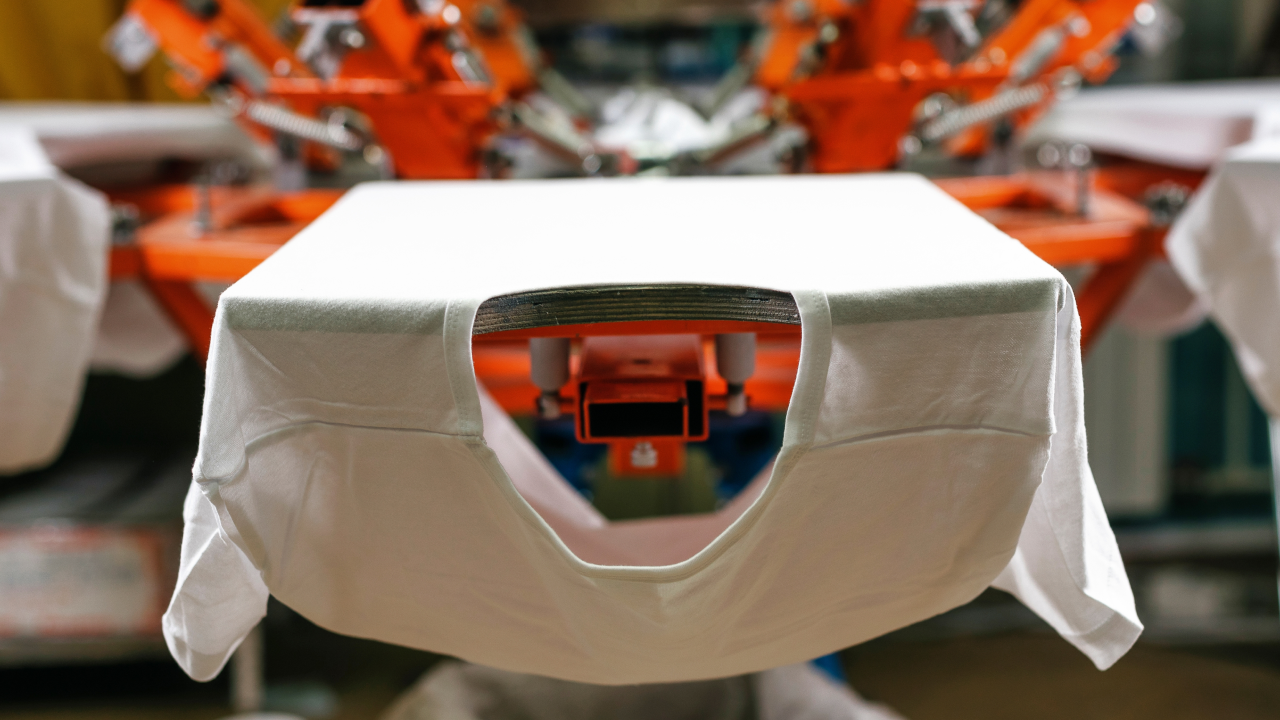

Start by identifying the kind of manufacturer that aligns with your business model. Some manufacturers focus on custom product development, helping to bring a unique idea to life from scratch. Others specialize in private label manufacturing, which allows you to brand an existing product as your own. You may also come across contract manufacturers that produce goods strictly based on your specifications, without contributing to product design. Batch size matters too. Some manufacturers are better suited for small production runs, while others are optimized for large-scale manufacturing. Knowing where you fit helps you filter options early.

Next, define your product specifications in detail. Manufacturers will expect clarity around key elements such as:

- Design and overall appearance

- Exact dimensions and tolerances

- Materials and finishes

- Compliance and regulatory requirements for your market

- Packaging type, labeling, and presentation

The more specific you are, the easier it is for a manufacturer to assess feasibility, pricing, and timelines.

At this stage, creating a working prototype can be extremely helpful. While not always required, a prototype provides manufacturers with a tangible evaluation tool and can expedite conversations. If a full prototype isn’t possible yet, you can still present clear supporting materials, such as sketches, reference photos, or written instructions that explain how the product should look and function.

Before sharing any detailed ideas, designs, or prototypes, make sure your intellectual property is protected. This could involve non-disclosure agreements or other legal safeguards, depending on your situation. Taking this precaution early helps reduce the risk of your ideas being copied and gives you more confidence when engaging with potential manufacturing partners.

Check our guide on copyright vs trademark for relevant information.

2. Decide if you want domestic or overseas manufacturing

Choosing between domestic and overseas manufacturing affects cost, quality control, timelines, and the level of control you can exert over production. There is no one-size-fits-all answer here. The right choice depends on your budget, order volume, quality expectations, and the level of hands-on involvement you require during the manufacturing process.

Domestic manufacturing often appeals to businesses that value closer oversight and faster turnaround times. Being geographically closer to your manufacturer makes it easier to monitor production, address issues quickly, and maintain consistent quality. Overseas manufacturing, on the other hand, is often chosen for its lower mass production costs and ability to handle large-scale orders, making it an attractive option for businesses focused on scaling or high-volume production.

Below is a side-by-side comparison to help you evaluate which option aligns better with your goals:

Factor | Domestic manufacturing | Overseas manufacturing |

Quality control | Easier to monitor production and perform quality checks | More difficult to oversee quality without third-party inspections |

Lead times | Shorter production and delivery timelines | Longer lead times due to shipping and customs |

Shipping costs | Lower shipping costs | Higher shipping costs, especially for air freight |

Production costs | Higher labor and manufacturing costs | Lower production and labor costs |

Production capacity | Smaller operations may struggle with bulk orders or multiple product lines | Large-scale facilities with higher production capacity |

Communication | Easier communication and faster responses | Time zone differences and potential language barriers |

Compliance and standards | Familiar labor laws, safety standards, and ethical practices | Must navigate international regulations and ethical considerations |

Minimum order quantity | More flexible for smaller runs | Higher minimum order quantities and smaller orders can be costly |

Economic impact | Supports local workers and the domestic economy | Broader supplier options across multiple regions |

Domestic manufacturing tends to suit businesses that prioritize quality control, faster delivery, smaller batch sizes, or ethical transparency. It can be especially useful for early-stage products, prototypes, or brands that market locally made goods. Overseas manufacturing is often better suited for businesses that need lower per-unit costs, higher production volumes, or access to specialized manufacturing capabilities not available locally.

Understanding these trade-offs early helps you choose a manufacturing path that supports both your short-term needs and long-term growth plans.

3. Research via Google Maps and online directories

Using a mix of Google Maps and established online directories helps you uncover credible options, compare suppliers, and avoid relying on guesswork or unverified recommendations.

For local or domestic manufacturing, Google Maps is a simple but effective starting point. Searching terms like “manufacturers near me”, “custom manufacturers near me”, or “contract manufacturing companies near me” can surface nearby factories and suppliers that may not appear in traditional search results. Google Maps listings often include reviews, photos, contact details, and business websites, which makes it easier to assess legitimacy and shortlist potential partners.

Online manufacturing directories offer a more targeted way to research suppliers, especially when you need specific capabilities or industry expertise. These platforms allow you to filter manufacturers by location, production type, materials, and certifications.

Well-known directories for domestic and North American manufacturers include:

- MFG: A large custom manufacturing marketplace connecting buyers with vetted manufacturers

- OpenMill: A USA-focused manufacturing directory covering North America

- Thomasnet: A product sourcing and supplier discovery platform for North American manufacturers, suppliers, and industrial companies

- Kompass International: A global business directory with detailed company profiles across industries

If you’ve decided to explore overseas manufacturing, there are dedicated directories that specialize in international suppliers and large-scale production. These platforms are widely used for sourcing manufacturers across Asia and other global regions:

- Alibaba: One of the largest global marketplaces for overseas manufacturers and suppliers

- Global Sources: A sourcing manufacturer focused on verified suppliers, primarily in Asia

- Made-in-China: A platform to connect buyers with Chinese manufacturers across multiple industries

- IndiaMART: A major directory for manufacturers and suppliers based in India

When using any directory, look beyond surface-level listings. Review company profiles carefully, check years in operation, certifications, minimum order quantities, and past client reviews when available. Combining directory research with Google Maps searches provides a broader and more reliable view of the manufacturing landscape, helping you build a strong shortlist before making direct contact.

4. Attend trade shows and local industry events

Trade shows and industry events provide the opportunity to meet manufacturers face-to-face, ask direct questions, and see real product samples. For small businesses, this hands-on exposure makes it easier to evaluate quality, capabilities, and overall fit before starting production.

If you’re sourcing locally, these events and resources are good places to start:

- ASD Market Week: A large wholesale retail merchandise show that connects brands with manufacturers, private label suppliers, and product developers across many industries

- North American Manufacturing Excellence Summit: A trade show that highlights operational excellence, production efficiency, and manufacturing best practices

- Manufacturing USA events directory: A centralized listing of upcoming manufacturing trade shows and local industry events across the country

Beyond discovering suppliers and finding wholesalers, trade shows enable in-depth conversations, allow you to compare options in one place, and provide the opportunity to review product examples firsthand. This direct interaction often helps you make more confident decisions when choosing a manufacturing partner.

5. Ask business owners and browse online forums

Another effective way to find reliable manufacturers is by learning from other business owners who have already gone through the process. Referrals and shared experiences can provide practical insights that aren’t always visible through directories or websites.

Social media platforms and online communities are useful starting points. Many business owners openly share supplier recommendations, sourcing challenges, and lessons learned in industry-specific groups.

Online forums dedicated to entrepreneurs and small business owners are also valuable resources for research. Platforms like Reddit host active discussions where users share honest feedback about manufacturers, production costs, quality issues, and communication experiences. Reading through these threads can help you identify common red flags, uncover trusted suppliers, and gain a better understanding of what to expect when working with specific manufacturers.

While opinions online should always be cross-checked, combining referrals and forum research with your own due diligence can add another layer of confidence when narrowing down your manufacturing options.

6. Do background checks

Background checks help you filter out unreliable suppliers early and give you a clearer picture of who is worth engaging further. Having a simple checklist can make this step more systematic and easier to repeat as you compare multiple options.

As part of your initial screening, consider checking the following:

- Confirm whether the manufacturer has a valid North American Industry Classification System (NAICS) code.

- Read customer reviews and testimonials to understand past client experiences.

- Check their Better Business Bureau (BBB) profile, if available, for complaints or accreditation status.

- Schedule a site visit, if possible to see their facilities and operations firsthand.

- Ask for relevant certifications and licenses, such as ISO standards.

- Review their website for professionalism, clarity, and up-to-date information.

- Verify that they provide accurate and complete contact details.

- Assess their customer service by noting response times and how clearly they answer inquiries.

These checks provide an initial assessment of a manufacturer’s capabilities, reliability, and reputation. However, they only tell part of the story. To fully understand whether a manufacturer is the right fit for your product and business, the next step is to speak with them directly. Asking the right questions during an interview will give you deeper insight into their manufacturing processes, expectations, and how they operate as a long-term partner.

7. Ask questions

At this stage, you should have a shortlist of manufacturers that meet your basic requirements. Now it’s time to dig deeper. Asking the right questions helps you confirm whether a manufacturer can truly support your product, budget, and long-term plans. This step applies whether you’re continuing your research independently or formally interviewing prospective manufacturing partners.

Focus your questions on areas that directly affect cost, quality, timelines, and flexibility. Key topics to cover include:

- Minimum order quantities required to place an order

- Sample pricing and whether sample fees can be applied to future production

- Production pricing structure and how costs change at different order volumes

- Payment terms, including deposits, payment schedules, and accepted payment methods

- Turnaround times for samples and full production runs

- Examples of similar items they have previously produced

- Quality control processes used during and after manufacturing

- Ability to accommodate custom orders or product modifications

- Shipping options, delivery timelines, and associated shipping costs

- Cost per unit at your expected order volume

- Defect policies covering replacements, refunds, or rework

- Sustainability efforts and ethical manufacturing practices

Pay close attention not just to the answers, but to how clearly and confidently the manufacturer responds. Transparent communication, realistic timelines, and willingness to explain their processes are often strong indicators of a reliable partner.

8. Compare quotes and samples from multiple manufacturers

This comparison helps you move beyond surface-level pricing and understand the real value each manufacturer offers.

Start by reviewing quotes carefully. Look at more than just the total cost. Pay attention to how pricing is broken down, including the cost per unit, tooling or setup fees, shipping, packaging, and any additional charges. A lower quote may seem attractive at first, but hidden costs or limited services can quickly offset the savings.

Samples play an equally important role in this stage. Evaluating physical samples allows you to assess build quality, materials, finishes, and overall consistency. Compare how closely each sample matches your specifications and whether the manufacturer accurately followed your instructions. This is often a strong indicator of how well they will perform during full production.

It’s also helpful to compare communication, responsiveness, and flexibility during this process. How quickly manufacturers provide quotes, answer follow-up questions, and adjust samples can reveal how they’ll behave once production begins.

9. Calculate your gross margins

This helps you determine whether a manufacturer’s pricing supports a profitable and sustainable business.

Gross margin represents the percentage of revenue you keep after covering the direct costs of producing your product. These costs usually include manufacturing, materials, packaging, and shipping. Understanding this number early helps you avoid choosing a manufacturing partner that leaves little room for operating expenses or future growth.

You can calculate gross margin using this formula:

Gross margin (%) = (selling price − total cost per unit) ÷ selling price × 100

For example:

If your selling price is $100 and your total cost per unit is $60, the calculation would look like this:

(100 − 60) ÷ 100 × 100 = 40% gross margin

Running this calculation for each manufacturer’s quote allows you to compare options more clearly. Higher margins generally mean more flexibility to invest in marketing, absorb unexpected costs, and scale production.

10. Check contract policies

Before choosing a manufacturer, take time to carefully review all contracts and written agreements. Even if pricing and margins look good, unclear or unfavorable terms can create problems later.

Focus on key policies such as cancellation and refund terms, including any penalties for changes or early termination. Review how the manufacturer handles production delays and what happens if turnaround schedules are not met. For overseas manufacturers, confirm how custom duties, tariffs, and taxes are handled, and check whether currency exchange rates can affect your final costs.

Also, examine closely any clauses related to quality control, defects, and the management of unexpected situations outside your control. A thorough contract review helps protect your business and ensures expectations are clearly defined before production begins.

11. Negotiate

Manufacturers expect some level of negotiation, especially if you’ve done your research and can clearly explain your needs and constraints.

This is the stage where you can discuss adjustments to minimum order quantities, payment terms, pricing tiers, or production timelines. In some cases, manufacturers may be willing to lower minimums for first-time orders, offer better pricing for repeat business, or revise payment schedules to reduce upfront risk. Contract policies, such as cancellation terms or lead times, may also be flexible depending on order size or long-term potential.

Approach negotiations professionally and with clear reasoning. Demonstrating an understanding of your costs, margins, and long-term plans makes it easier to reach terms that work for both parties.

12. Order your first items

This initial production run is a crucial validation step, as it demonstrates how well the manufacturer adheres to your specifications under actual conditions.

When the first batch arrives, inspect the items carefully before moving forward with larger orders. Check for consistency in design, dimensions, materials, packaging, and overall quality. Take note of any errors, defects, or deviations from what was agreed upon, even if they seem minor. Document these issues clearly, including photos and written notes, so they can be addressed promptly.

This first order is not just about receiving products, but about evaluating performance. How the manufacturer responds to feedback, fixes mistakes, and communicates during this stage often reflects how reliable they will be in future production runs.

Is a manufacturer the same as a supplier?

A manufacturer and a supplier are related, but they are not the same.

A manufacturer is the company that actually makes the product. They handle production activities, including sourcing raw materials, operating machinery, assembling components, and producing finished goods according to your specifications. When you work directly with a manufacturer, you’re dealing with the source of production.

A supplier, on the other hand, is a broader term. Suppliers may sell finished products, raw materials, or components, but they do not always manufacture the items themselves. Some suppliers act as intermediaries between you and the manufacturer, while others focus on distribution rather than production.

Here’s a quick comparison to highlight the differences:

Aspect | Manufacturer | Supplier |

Primary role | Produces goods from raw materials or components | Provides products, materials, or goods to businesses |

Involvement in production | Directly involved in making the product | May or may not be involved in production |

Customization | Often supports custom or made-to-spec products | Typically offers ready-made products with limited customization |

Pricing | Usually lower per unit when buying in bulk | Often higher due to added markup |

Relationship | Direct production partnership | Transactional or intermediary-based relationship |

Use case | Best for custom products and long-term production | Useful for sourcing materials or ready-made items |

Knowing whether you need a manufacturer or a supplier depends on your product goals. If you’re creating a custom product or scaling production, working directly with a manufacturer is usually the better fit.

Why does finding the right manufacturer matter?

The partner you choose can have a direct impact on your product quality, costs, timelines, and long-term business stability. A good fit supports growth, while the wrong one can introduce risks that are difficult and expensive to fix later.

Here are the key reasons why choosing the right manufacturer matters:

- Product quality consistency affects customer satisfaction and brand reputation

- Cost control and predictable pricing that support healthy profit margins

- Reliable production timelines that help you meet launch dates and customer expectations

- Scalability, ensuring the manufacturer can grow with your business as demand increases

- Clear communication and transparency throughout the production process

- Strong quality control processes that reduce defects and returns

- Ethical and regulatory compliance that protects your brand and market access

- Long-term partnership potential rather than a short-term transactional relationship

Taking the time to evaluate manufacturers carefully helps you build a more resilient supply chain and sets a stronger foundation for sustainable growth.

What is the cost of hiring a manufacturer?

Hiring a manufacturer can cost anywhere from a few dollars per unit to several hundred dollars per unit, depending on your product and production requirements. There is no fixed price, as manufacturing costs vary widely depending on the product being produced and its production method.

Several factors influence the overall cost. Product volume plays a significant role, as higher order quantities typically result in a lower cost per unit. Materials also affect pricing, especially if you require premium, custom, or regulated materials. Products that require specialized capabilities, such as precision machining, electronics, or custom tooling, typically cost more due to the equipment and expertise required.

Labor costs vary depending on the location of the manufacturer and the complexity of the production process. Timelines matter as well. Rush orders or tight deadlines often come with higher costs. Pricing can also change based on whether you’re manufacturing a complete product, assembling pre-made components, or producing a single part.

Additional considerations include laws, rules, and regulatory requirements, which may add testing, certification, or compliance costs. Shipping is another key factor, especially for overseas manufacturing, where freight, customs duties, and tariffs can significantly affect your total expense.

Understanding these cost drivers helps you set realistic expectations and compare manufacturers more accurately before committing to a production decision.

Frequently asked questions

There isn’t a single website dedicated to all manufacturer searches, but several platforms are widely used depending on your location and needs. Online directories such as Thomasnet, MFG, Kompass, and OpenMill are commonly used for finding domestic manufacturers. For overseas manufacturing, platforms like Alibaba, Global Sources, and Made-in-China are popular options. Using multiple directories alongside Google searches helps you find more reliable matches.

A manufacturing company can be identified by its direct involvement in producing goods rather than reselling them. Signs include clear production capabilities listed on their website, factory photos or videos, industry certifications, a valid NAICS code, and the ability to discuss materials, machinery, and quality control processes in detail. Verifying reviews, contact information, and business registrations can also help confirm legitimacy.

Outsourcing manufacturing is often cheaper, especially when working with overseas manufacturers due to lower labor and production costs. However, lower unit pricing does not always mean lower total costs. Shipping, duties, quality control, communication challenges, and higher minimum order quantities can offset savings. Whether outsourcing is cheaper depends on your product, volume, quality standards, and long-term business goals.

Begin your e-commerce journey with Network Solutions

Finding the right manufacturer is a critical step in bringing a product to market and building a business that can grow sustainably. As outlined throughout this guide, the process works best when it’s approached methodically, from defining your product needs and researching options to comparing quotes, reviewing contracts, and placing your first order.

Taking the time to carefully evaluate manufacturers helps reduce risks associated with quality, costs, and delays. More importantly, it allows you to form a partnership that aligns with your product standards, operational needs, and long-term goals. By following a structured approach and asking the right questions at each stage, you put yourself in a stronger position to choose a manufacturer that supports both your immediate launch and future growth.

If you’re preparing to bring a product to market, having the right manufacturing partner is only part of the equation. You also need a strong online presence to sell and grow your business. At Network Solutions, we offer tools that help you take the next step, from domain registration and reliable web hosting to an AI-powered website builder and e-commerce solutions designed to get you online faster. With the right foundation in place, you can focus on launching your products, reaching customers, and building a brand that’s ready to scale.